EOS: Recognized expertise in precision mechanics to cover all your needs

Since its creation in 2010, EOS has established itself as a benchmark in precision mechanics. Based in the Lyon region, our dynamic and innovative company offers manufacturers in all sectors complete solutions for the design, manufacture and retrofit of special industrial machines, as well as machining services.

Thanks to our know-how and the skills of our experienced team, we can meet the specific needs of every customer, from SMEs to major corporations, in sectors as varied as aeronautics, automotive, space and nuclear power.

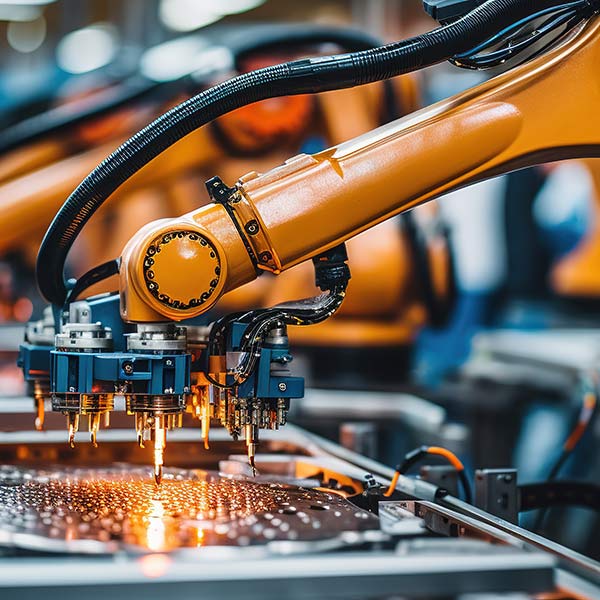

Design and manufacture of special machines

EOS excels in creating special machines to meet the automation needs of industrial production processes. Thanks to its in-depth expertise and careful attention to customer needs, EOS develops tailor-made solutions.

These specific machines are designed from an idea, a specific need or a pre-established specification.

The rigorous EOS design process begins with a meticulous mechanical study to define the principles and choose the most suitable equipment. The EOS design office, specialized in mechanics, electronics and automation, plays a crucial role in validating technologies and ensuring project feasibility.

Modern industry demands innovative solutions tailored to specific needs. In this context, choosing the right supplier for the design and manufacture of special machines is crucial for companies wishing to optimize their production. EOS, an expert in this field, offers manufacturers in all sectors in France and Europe a complete service including design, manufacture and on-site installation, as well as staff training for fully autonomous use of the machines.

Since its creation, EOS has specialized in the design of special industrial machines, including transfer machines, process machines… Our company meets the requirements of customers in all sectors, adapting to the standards and constraints of each activity to offer totally unique solutions.

Our customer base includes well-known companies such as Safran, Airbus, AIA (aeronautics), Framatome (nuclear), Continental (automotive) and Ariane (space), demonstrating our ability to meet a wide range of industrial needs.

Our team’s know-how enables us to manufacture all types of machines. Your budget and deadline are the only limits to what we can offer you.

Industrial AGV and tube bending

EOS’expertise in precision mechanics also extends to industrial AGVs / MGVs and tube bending. AGVs (autonomous guided vehicles) and MGVs (manual guided vehicles) are capable of transporting heavy loads in a variety of industrial environments.

Our company also offers retrofit services for these systems, including Snox AGVs, for which we have particular expertise.

Autonomous Guided Vehicles

EOS stands out for its ability to design industrial AGVs entirely tailored to the specific needs of each customer. Rather than offering standardized solutions, our approach is to create tailor-made AGVs, fully aligned with our customers' operational requirements. This philosophy places the customer at the heart of the design process, enabling him to benefit from a perfectly adapted solution without compromise. Our expertise lies in our ability to understand each customer's unique needs in depth.

Thanks to our design office specialized in mechanical engineering and automation, our mechanical engineering workshop and our commissioning team, we guarantee the implementation of an innovative, efficient, maintainable and upgradeable solution that perfectly meets your operational challenges. This means that further improvements can be made over time to extend the service life of the vehicles. Our vehicles are multi-purpose, capable of transporting various types of loads, whether pallets, products in crates or on special structures (tools / interfaces).

We can design solutions for loads ranging from a few tens of kilos to several tens of tons, meeting a wide variety of transport capacity requirements. Our achievements cover a wide range of fields, from aeronautics and aerospace to plastics, nuclear, food processing, pharmaceuticals and many others. This versatility demonstrates our ability to adapt to the specific requirements of various industries.

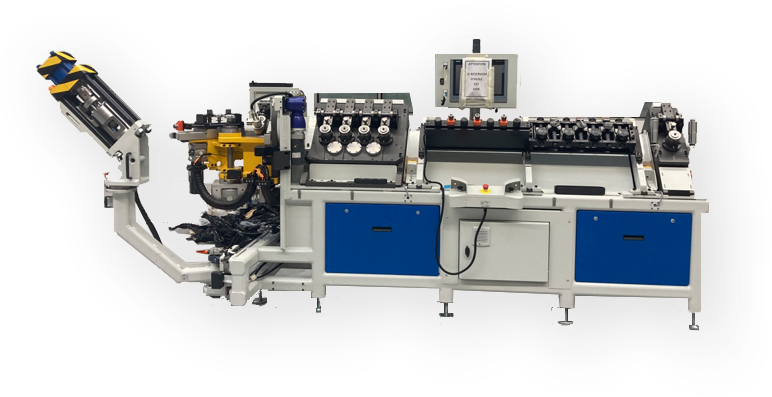

Design of custom bending machines and tooling

When it comes to tube bending, EOS offers complete solutions, from the design of your bending machines to the manufacture of the necessary parts, for an integrated, high-quality service. Some of our staff have over 30 years’ experience in bending machine design.

Whether creating new machines, retrofitting, manufacturing bending tooling, or maintaining bending machines, EOS guarantees its customers flawless reliability. Our expertise, and the diverse backgrounds of our engineers and technicians, enable us to respond precisely to current industry requirements and the specific constraints of your business.

Specializing in Siemens systems for bending machines, EOS excels in CNC bending machine design. We work with you to analyze your needs and tailor our proposals to your business requirements and industry standards. We also design and manufacture bending tools specifically adapted to your machine, whether it’s one of our own design or not. Whether you need to bend small-diameter tubes or large-scale industrial parts, our tools are designed to meet your exact requirements. We offer you unrivalled flexibility in the design and manufacture of bending machines, and know how to adapt to the most demanding specifications.

Rebuilding bending machines: the retrofit option

In addition to designing and manufacturing tube bending machines, EOS also specializes in rebuilding bending machines. This retrofit service makes it possible to keep an existing machine, which is often difficult to replace, at lower cost, while adapting it to the latest technologies. Taking into account your budget, desired precision and cycle time, EOS offers you an efficient upgrade. In this way, you can keep your machines up and running while adapting to current industry requirements, including safety.

What’s more, retrofitting will help your company achieve its sustainable economic and environmental objectives, with an average of 90% of the machine’s mass retained.

Machining expertise in Lyon:

production of all your mechanical parts

Precision machining is a field in which EOS particularly excels,

both in the design and manufacture of custom parts for industry.

Our machine park, comprising 2 lathes for turning and 4 machining centers for milling, enables us to produce small and medium-sized series of mechanical parts with great precision. EOS is committed to supplying high quality parts, ensuring consistency in production through rigorous quality control, reinforcing its reputation in the sector.

Backed by genuine know-how, in-depth knowledge of industrial standards and state-of-the-art machinery, our company guarantees consistent quality for the machining of technical parts, whatever the number of items ordered (small series, from 20 to 1000 items). In particular, we use a state-of-the-art XM inspection machine for a rigorous and strictly supervised quality control process.

EOS's reputation for manufacturing industrial parts is based on the unquestionable technical expertise and long-standing experience of its technicians and engineers, who can produce any technical part, from the simplest to the most complex.

Our commitment to impeccable quality and follow-up

At EOS, every project is treated with the utmost care, and we make sure to deliver an impeccable quality of service.

For all our services, from theindustrial AGV to the tube bending, EOS is committed to providing you with complete support, from design to on-site installation, including training of your on-site personnel in the use of EOS tube bending machines. special machines, new or retrofitted. We systematically offer you an in-depth interview prior to the audit in order to better understand your needs. Each step is validated in your company.

Our company also stands out for its machining expertise in Lyon and its ability to adapt to the specific requirements and standards of each sector, making EOS a partner of choice for manufacturers looking for precision engineering solutions.